- Careers

- Media & Events

- Downloads

-

- Europe

- Belgium

- Germany

- United Kingdom

- France

- Austria

- Switzerland

- Czech Republic

- North America

- Canada

- USA

- Middle East & Africa

- United Arab Emirates

- Saudi Arabia

WOLFFKRAN'S heritage of 100+ years in providing lifting solutions to shipyards requires innovative solutions

At WOLFFKRAN we use the latest lifting technology to maximise the efficiency of your yard. Our installations on travelling portals offer flexible lifting solutions that adapt perfectly to your environment.

We are world leaders in delivering heavy lifting solutions and have established a portfolio of successful shipyard solutions all over the world. Our comprehensive range of tower cranes with varying capacities means we have the capabilities to meet numerous demands.

The fully adaptable modular design brings all the benefits of a custom-built single-purpose crane without the long lead times and significant costs.

This makes the WOLFFKRAN approach the most efficient solution to meet multiple lifting needs across shipyards of all sizes.

WOLFFKRAN is the perfect partner for the shipyard

industry

The most important part of a ship’s journey is the time it spends in the dock. During the crucial time spent on maintenance and repairs, you need a partner you can rely on!

WOLFFKRAN International AG

Baarermattstrasse 6, 6340 Baar

+41 41 766 85 00

Exceptional savings compared to custom-built shipyard cranes and higher lifetime value

Superior tower crane range to meet all lifting needs in terms of capacity and reach

Modular solutions to match client requirements, built to any track width, portal height, and existing infrastructure

Faster hook speeds offer improved operating performance

Elevated driver position and WOLFF Fine Positioning Controls allow for the exact position of heavy loads

Short delivery lead times and complete onsite assembly within one week

Our shipyard application solution works by utilising and, if required, adapting our standard range of tower cranes, placed on a moveable and fully adjustable base to meet the dynamic challenges faced in the shipyard.

A strong base for all situations: our experienced team of engineers will work with you to create the perfect solution for your shipyard, our customised bases can be specified for any track width and adapted to match your exact lifting capacity requirements. Giving you all the power and performance that are the trademarks of WOLFFKRAN cranes.

Using all of the advanced WOLFFKRAN modular components our cranes can then adapt to any requirements in terms of height, reach and capacity

and come in two model variants:

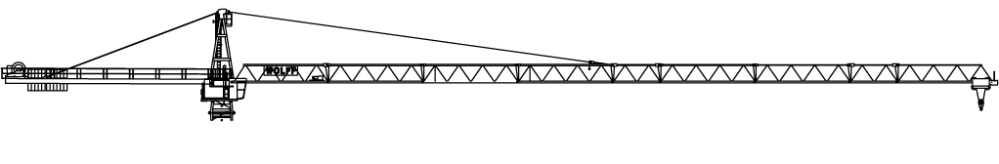

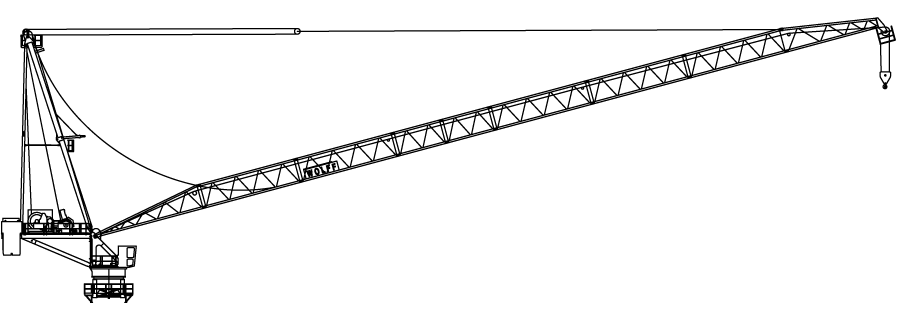

Trolley Jib – The classical design allows

for high cycle speeds and greater jib radius

Luffing jib – offering maximum power and

efficiency in space restricted situations

At WOLFFKRAN we offer a complete solution for the shipyard market, this includes:

Purchase options

We offer a large variety of payment options and support you with financing

solutions

Cost-effective

Modular solutions backed up by proven technology

One-stop shop

Taking care of all your heavy lifting requirements, from logistics to site set-up and operating

One-stop shop

Taking care of all your heavy lifting

requirements, from logistics to site set up and operating

Lifting consultancy

Working with you to identify and plan

the right solution for your installation

Service support

Fast installation with readily available service and spare parts

Level luffing

The load always remains at the

same height while moving the jib up

and down

Protection against marine influences

100+ years of experience in customized painting, corrosion treatment and IP insulation for marine cranes

WOLFFKRAN is committed to minimising impact on the environment wherever it can:

LOCATION

Dordrecht, Netherlands

CRANE SPECIFICATIONS

Jib Lenght: 65 m

Max. Lifting Capacity: 12 t

Tip Load Capacity: 3.3 t

Crane Base: Travelling portal 5.5 x 6 m

LOCATION

Antwerp, Belgium

CRANE SPECIFICATIONS

Jib Lenght: 80 m

Max. Lifting Capacity: 40 t

Tip Load Capacity: 10 t

Crane Base: Travelling portal 9 x 10 m

LOCATION

Linz, Austria

CRANE SPECIFICATIONS

Jib Lenght: 65 m

Max. Lifting Capacity: 16.5 t

Tip Load Capacity: 3.2 t

Crane Base: Travelling portal 4 x 4 m